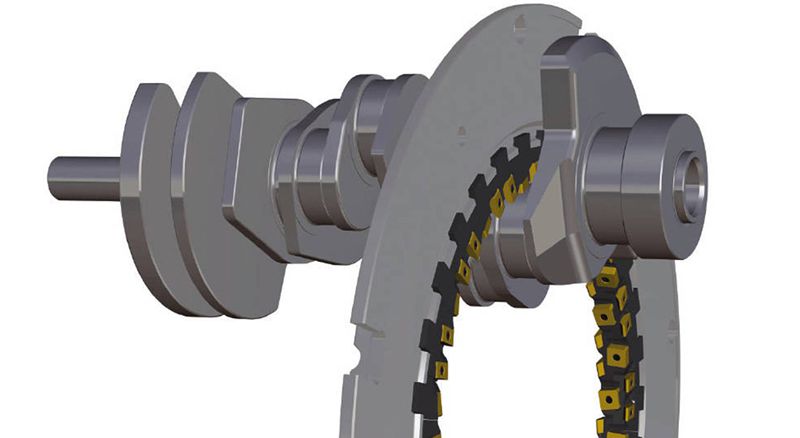

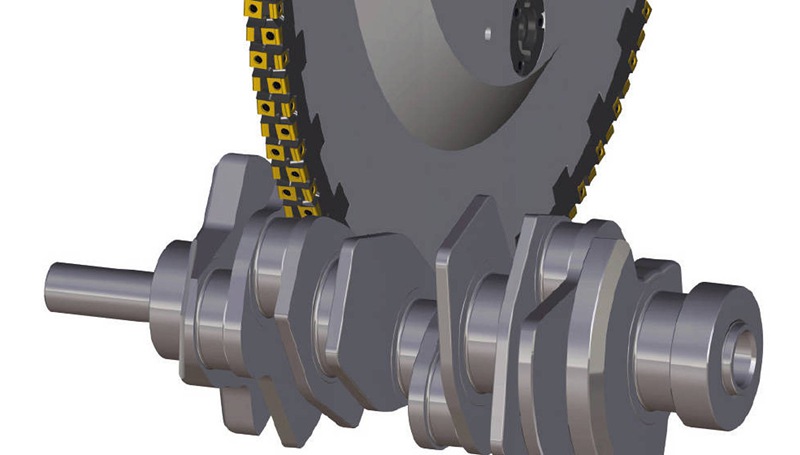

Crankshaft machining is a critical process in various industries, particularly in automotive and aerospace sectors. The use of carbide inserts in milling tools has revolutionized this process by offering enhanced performance, precision, and durability. This article delves into the benefits and applications of carbide crankshaft inserts milling tools, focusing on the high-quality products offered by Halnn.

Carbide inserts are cutting tools made from a composite material consisting of carbon and tungsten. Known for their exceptional hardness and resistance to wear, carbide inserts are ideal for high-speed machining processes like crankshaft milling. These inserts maintain their cutting edge at higher temperatures, which is crucial for machining hard materials such as crankshafts.

There are several types of carbide inserts used in crankshaft machining, each designed for specific applications. These include:

Standard Inserts: Suitable for general-purpose machining.

High-Precision Inserts: Designed for applications requiring extremely tight tolerances.

Specialized Inserts: Custom inserts for unique machining conditions.

Carbide inserts can withstand extreme temperatures and resist wear, resulting in a longer tool life and fewer replacements. This durability is particularly beneficial in crankshaft milling, where the tools must endure high levels of stress and heat.

The hardness of carbide allows for higher cutting speeds and greater precision, which improves overall machining efficiency. Carbide inserts maintain a sharp cutting edge longer than other materials, ensuring consistent performance and superior finishes.

While the initial cost of carbide inserts may be higher, their extended lifespan and reduced need for frequent replacements and maintenance lead to significant long-term cost savings.

Halnn offers a comprehensive range of carbide crankshaft inserts designed for various machining needs. Our products are renowned for their superior quality and performance, providing reliable solutions for crankshaft machining.

Halnn carbide inserts feature advanced coatings and optimized geometries, ensuring maximum cutting efficiency and longevity. Our inserts are designed to handle the most demanding machining conditions, delivering exceptional results consistently. Case studies from satisfied customers highlight significant improvements in machining performance achieved with Halnn inserts.

In the automotive industry, carbide inserts are used to machine crankshafts with high precision and efficiency, ensuring the reliability and performance of engines. Halnn carbide inserts help automotive manufacturers achieve tighter tolerances and smoother finishes, enhancing the overall quality of their products.

Besides automotive industry, carbide crankshaft inserts are used in various other industries, including marine and heavy machinery manufacturing. Halnn versatile carbide inserts cater to a wide range of applications, offering unmatched performance across different sectors.

When selecting carbide inserts, consider factors such as the material of the crankshaft, machining conditions, and specific requirements of the milling process. Choosing the right insert geometry and coating can significantly impact performance and tool life.

Halnn provides expert guidance to help customers choose the appropriate inserts for their specific applications. Our team of specialists works closely with clients to understand their needs and recommend the best solutions for optimal performance and efficiency.

Regular maintenance, such as cleaning and proper storage, can significantly extend the life of carbide inserts. Ensuring that the inserts are free from debris and properly lubricated will help maintain their cutting efficiency.

Understanding common issues, such as chipping or wear, and knowing how to address them can help maintain the performance of carbide inserts. Halnn offers comprehensive support and troubleshooting tips to ensure that our customers get the most out of their carbide inserts.

Advancements in carbide material science and insert design continue to improve the performance and lifespan of these tools. Halnn stays at the forefront of these innovations, constantly enhancing our product offerings to meet the evolving needs of the industry.

The future of crankshaft machining looks promising, with ongoing innovations in carbide insert technology paving the way for even greater efficiency and precision. Halnn is committed to leading this progress, providing cutting-edge solutions for the next generation of machining challenges.

Carbide crankshaft inserts milling tools offer numerous benefits, including enhanced durability, improved performance, and cost-effectiveness. Halnn high-quality carbide inserts are designed to meet the demanding needs of modern crankshaft machining. For more information or to purchase Halnn products, contact our sales team today.

Carbide crankshaft inserts milling tools are specialized cutting tools made from a composite material consisting of tungsten carbide. These tools are designed for the precise and efficient machining of crankshafts, providing superior wear resistance, durability, and cutting performance compared to traditional materials.

The primary advantages of using carbide inserts for crankshaft milling include:

Increased durability: Carbide inserts have a longer lifespan due to their high wear resistance.

Enhanced cutting performance: They maintain a sharp cutting edge for longer periods, ensuring consistent precision.

High-temperature resistance: Carbide can withstand higher temperatures without losing its hardness, making it ideal for high-speed machining.

Cost-effectiveness: Although initially more expensive, their durability reduces the frequency of replacements and maintenance, leading to long-term cost savings.

Choosing the right carbide inserts involves considering factors such as:

Material of the crankshaft: Different materials require different types of carbide inserts.

Machining conditions: Factors like cutting speed, feed rate, and coolant use affect the choice of inserts.

Insert geometry and coating: Selecting the appropriate geometry and coating can enhance performance and tool life. Consulting with experts, such as those at Halnn, can help in making the right choice.

Common types of carbide inserts used in crankshaft milling include:

Standard Inserts: For general-purpose machining.

High-Precision Inserts: For applications requiring tight tolerances.

Specialized Inserts: Custom-designed inserts for unique machining conditions or specific crankshaft materials.

Yes, carbide inserts are versatile and can be used for both external and internal crankshaft milling. They are designed to handle various aspects of crankshaft machining, ensuring precision and efficiency in both applications.

Proper maintenance and care for carbide crankshaft inserts include:

Regular cleaning: Keeping the inserts free from debris to prevent wear and damage.

Proper storage: Storing inserts in a clean, dry environment to avoid corrosion.

Timely replacement: Monitoring insert wear and replacing them when necessary to maintain optimal machining performance.

Common issues include:

Chipping: Caused by improper handling or excessive cutting forces. Solution: Ensure proper setup and handling of tools.

Wear: Due to prolonged use or unsuitable cutting conditions. Solution: Adjust cutting parameters and use appropriate coatings.

Breakage: Often a result of incorrect insert selection or severe machining conditions. Solution: Choose the right insert for the specific application and ensure proper machine setup.

Halnn carbide crankshaft inserts milling tools are renowned for their high quality, advanced coatings, and optimized geometries. They are designed to handle the most demanding machining conditions, delivering exceptional results consistently. Halnn offers expert guidance to help customers choose the right inserts, ensuring optimal performance and efficiency.

Recent innovations in carbide insert technology include advanced coating techniques, improved insert geometries for better chip control, and the development of more heat-resistant carbide grades. Halnn stays at the forefront of these innovations, continuously enhancing our product offerings to meet the evolving needs of the industry.

You can purchase Halnn carbide crankshaft inserts milling tools directly from our website or by contacting our sales team. Our experts are available to provide detailed product information and assist you in selecting the best tools for your specific needs.

Mail address: halnntools@halnn-group.com

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone