Diamond piston tools are specialized cutting instruments embedded with diamond particles, which can be either synthetic or natural. These tools are specifically designed for the high-precision machining of pistons, which are crucial components in various engines and machinery. Diamond piston tools encompass a range of products, including inserts, cutters, and reamers, each tailored to meet the stringent demands of piston manufacturing.

Diamond tools are invaluable in piston machining due to their exceptional wear resistance, precision, and efficiency. These tools enable manufacturers to achieve superior surface finishes and maintain tight tolerances, which are essential for the optimal performance of pistons. The durability of diamond tools significantly reduces the frequency of tool changes and downtime, thereby enhancing overall productivity and cost-effectiveness in the manufacturing process.

Diamond piston tools are crafted from high-quality diamond particles bonded to a substrate, typically composed of tungsten carbide. The diamond particles, known for their unrivaled hardness, are sintered together under high pressure and temperature to form a robust and durable cutting edge. The bonding matrix secures the diamond particles in place and adds toughness to the tool, allowing it to withstand the rigors of high-speed machining.

The superior performance of diamond piston tools is attributed to several key properties:

Extreme Hardness: Diamonds are the hardest known material, enabling these tools to cut through tough materials with remarkable ease.

Thermal Conductivity: High thermal conductivity allows for rapid heat dissipation, reducing the risk of thermal damage to both the tool and the workpiece.

Chemical Stability: Diamonds are chemically inert and do not react with most materials, ensuring consistent performance and longevity even in challenging machining environments.

Diamond piston tools are employed in various industries due to their superior performance and reliability. Key sectors include:

Automotive: Essential for manufacturing high-performance pistons with precise tolerances and superior surface finishes.

Aerospace: Used in the production of critical piston components where precision and durability are paramount.

Heavy Machinery: Employed in the machining of large pistons and related components requiring high wear resistance and longevity.

Diamond piston tools excel in a variety of machining processes, including:

Turning: Achieving high precision and surface quality on piston surfaces.

Milling: Used for contouring and shaping piston components with intricate designs.

Drilling: Ensuring accurate and clean holes in piston parts.

Honing: Providing a superior finish and precise dimensions to piston bore surfaces.

The benefits of using diamond tools for piston machining are numerous:

Enhanced Surface Finish: Produces smoother surfaces, reducing friction and wear.

Reduced Machining Time: Higher cutting speeds and feed rates lead to faster production cycles.

Extended Tool Life: Superior wear resistance results in longer intervals between tool changes, increasing overall productivity.

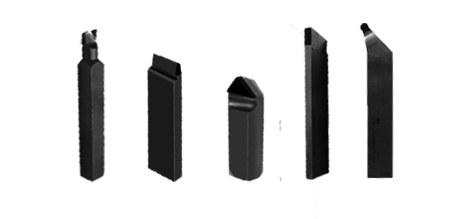

Diamond tools for piston machining come in various standard types, such as:

Inserts: Replaceable cutting edges that can be indexed and rotated, ensuring prolonged tool life.

Cutters: Solid tools used for both roughing and finishing operations, providing versatility in machining processes.

Reamers: Precision tools designed to enlarge holes with high accuracy, ensuring exact dimensions.

The geometry of diamond piston tools is crucial for achieving optimal performance. Important considerations include:

Rake Angle: Influences cutting efficiency and chip flow.

Clearance Angle: Affects the tool's ability to avoid rubbing against the workpiece, which can impact surface finish.

Edge Preparation: Ensures the cutting edge is sharp and durable, reducing the risk of chipping and enhancing tool life.

Diamond tools can be customized to meet specific piston machining requirements, such as:

Complex Profiles: Tools designed for intricate shapes and contours, enabling precise machining of complex piston geometries.

Special Tool Geometries: Custom angles and edge preparations tailored for unique applications, optimizing performance and efficiency.

Selecting the right diamond tool depends on the material of the piston being machined. Considerations include:

Non-Ferrous Metals: Diamond tools excel in cutting aluminum, copper, and their alloys, providing excellent surface finishes and prolonged tool life.

Composites: Effective in machining composite materials without causing delamination, ensuring high-quality results.

Factors influencing the selection of diamond tools include:

Cutting Speed: Higher speeds improve efficiency but require tools with excellent thermal stability to prevent overheating.

Feed Rate: Determines the rate at which material is removed and impacts surface finish and tool wear.

Depth of Cut: Affects the tool's performance and the quality of the machined surface, requiring careful selection based on the specific application.

Evaluating the cost-effectiveness of diamond tools involves:

Initial Investment: While the upfront costs are higher compared to conventional tools, the long-term benefits often justify the investment.

Tool Longevity: Longer tool life reduces the frequency of replacements and downtime, resulting in lower operational costs over time.

Machining Efficiency: Faster production rates and improved quality offset the initial expenses, providing overall cost savings.

Proper setup and alignment are crucial for optimal performance. Ensure:

Correct Installation: Tools are securely and accurately mounted to prevent misalignment and vibrations that could affect machining quality.

Alignment Checks: Regularly verify alignment to maintain precision and avoid potential issues that could lead to tool wear or damage.

Optimize cutting parameters to enhance tool life and machining quality:

Speed and Feed Rates: Adjust based on the material being machined and the desired finish, balancing efficiency and tool wear.

Depth of Cut: Set appropriately to achieve the best compromise between material removal rate and tool longevity.

The use of coolant and lubrication is vital in diamond tool machining:

Coolant Application: Prevents overheating and reduces thermal stress on both the tool and the workpiece, enhancing tool life and performance.

Lubrication: Minimizes friction and helps in chip removal, ensuring a cleaner and more efficient machining process.

Regular maintenance procedures include:

Cleaning: Remove debris and residues from the tool surface to prevent buildup that could affect performance.

Inspection: Check for wear, chipping, or other damage to ensure tools are in good condition and ready for use.

Maintaining cutting edges is essential for prolonged tool life:

Edge Honing: Periodically hone edges to restore sharpness and ensure consistent cutting performance.

Refurbishment: Utilize professional refurbishment services to extend the usability of worn tools, offering a cost-effective alternative to replacement.

Prevent damage to diamond tools by following proper storage and handling practices:

Storage: Keep tools in a clean, dry environment to avoid contamination and prevent corrosion.

Handling: Handle with care to prevent chipping or other damage that could compromise tool integrity and performance.

Diamond piston tools play a crucial role in achieving high precision, durability, and efficiency in piston machining. Their superior properties, such as extreme hardness and thermal conductivity, make them indispensable in industries like automotive, aerospace, and heavy machinery. Proper selection, usage, and maintenance of these tools ensure optimal performance and cost-effectiveness.

Explore further resources, contact experts, or consider adopting diamond tools from Halnn group for your piston machining needs to experience enhanced efficiency and precision in your manufacturing processes.

Diamond piston tools are specialized cutting tools made with synthetic or natural diamonds, designed for machining pistons with high precision, durability, and efficiency. These tools are known for their extreme hardness and ability to maintain sharp cutting edges, providing superior performance in piston manufacturing processes.

Diamond tools are used in piston machining because they offer several benefits, including exceptional wear resistance, high thermal conductivity, and chemical stability. These properties result in longer tool life, improved surface finish, and faster machining speeds, making them ideal for high-precision applications in industries like automotive and aerospace.

Diamond piston tools are made using synthetic or natural diamonds bonded together with a metal matrix. The synthetic diamonds are engineered to provide consistent quality and performance, while the metal matrix ensures the diamonds are securely held in place during machining operations.

Diamond piston tools are commonly used in industries that require high precision and durability in their machining processes. These industries include automotive, aerospace, heavy machinery, and manufacturing, where high-performance piston components are essential for optimal operation.

Diamond piston tools are versatile and can be used for various machining processes, including turning, milling, drilling, and honing. These tools excel in machining hard and abrasive materials, providing superior surface finish and dimensional accuracy in piston components.

Selecting the right diamond piston tool involves considering factors such as the material of the piston being machined, the desired cutting speed, feed rate, and depth of cut. It's essential to choose a tool with the appropriate geometry and properties for your specific machining conditions to achieve optimal performance and efficiency.

The benefits of using diamond piston tools in piston machining include:

Enhanced surface finish

Extended tool life

Higher machining speeds

Reduced tool wear and maintenance

Improved overall machining efficiency and productivity

To maintain diamond piston tools, it's important to follow routine maintenance procedures, such as cleaning and inspecting the tools regularly. Edge retention techniques, like honing, can help keep the cutting edges sharp. Proper storage and handling are also crucial to prevent damage and contamination.

Yes, diamond piston tools can be customized to meet specific machining requirements. Customization options include modifying the tool geometry, such as rake angle, clearance angle, and edge preparation, to suit particular piston machining applications and achieve desired results.

While diamond piston tools may have a higher initial investment compared to other cutting tools, their extended tool life and superior performance can result in lower overall machining costs. The reduced need for frequent tool changes and maintenance, along with improved machining efficiency, contribute to cost-effectiveness in the long run.

Diamond piston tools offer significant advantages over conventional cutting tools, such as carbide or ceramic tools. Their superior hardness and wear resistance allow for longer tool life and higher cutting speeds, making them more efficient for high-precision machining applications. Additionally, diamond tools provide better surface finish and dimensional accuracy, essential for critical piston components.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone