1. The position of Halnn PCBN inserts in the wind power field benefits from its significant advantages in many aspects. The specific analysis is as follows:

1. Halnn’s BN-H200 PCBN inserts has excellent wear resistance, which allows it to effectively deal with the wear of the workpiece material during processing, thereby significantly increasing the service life of the tool.

2. When turning high-hardness materials such as wind turbine bearings, the BN-H200 grade PCBN inserts can improve the processing technology and increase production efficiency. Its solution can be comparable to imported brands.

3. Halnn’s PCBN inserts BN-H200 not only occupies more than 60% of the domestic market, but also occupies a place in the markets of developed countries such as Europe and the United States.

Analysis of successful cases

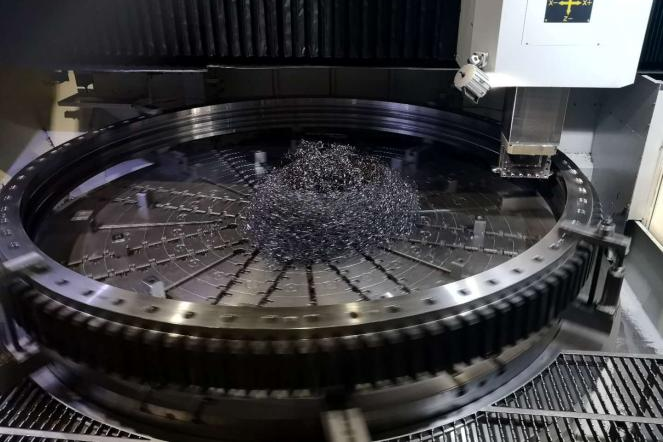

1. Halnn PCBN inserts BN-H200 processing case of outer ring of 2750 wind turbine bearing

Processing difficulties: (1) Large cutting depth of 1-1.5mm; (2) Strong discontinuity of oil groove and oil holes; (3) Insufficient wear resistance and out-of-tolerance dimensions.

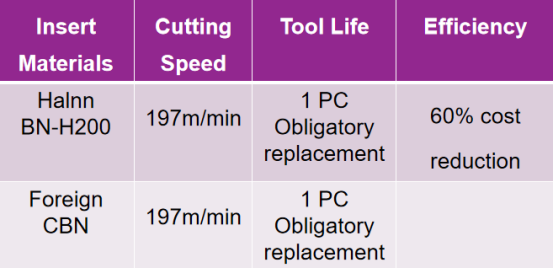

Summary: Under the same cutting parameters, the cost of Halnn PCBN inserts is 60% lower than that of imported inserts.

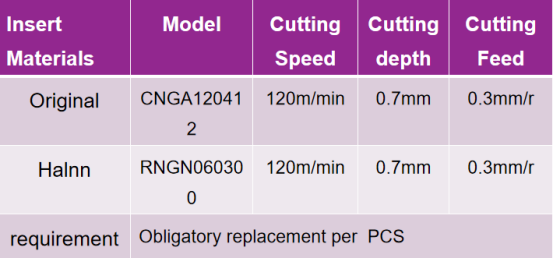

1. Comparison of Halnn PCBN inserts BN-H200 with imported CBN for machining fine turning tooth top outer circle

One step:Fine turning of the outer circle of the tooth top

Original insert: CNGA120412

Machining parameter:VC=119m/min,f=0.3

ap=0.7,diameter=725

Tool life:2PCS/Edge

Halnn insert:BN-H200 RNGN090300

Machining parameter:VC=119m/min,f=0.3

ap=0.7,Diameter=725

Tool life:3PCS/Edge

Comparison of Halnn PCBN inserts BN-H200 with foreign imported CBN processing finishing end face and inner hole

Facing the inner hole of a large-diameter gear ring, the roughness of the Halnn BN-H200 inserts can still be controlled within 0.6 after processing the 300-meter deep inner hole. The processing time of a single piece is shortened from the previous 24 minutes to 8 minutes, and the processing efficiency is increased by 3 times.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone