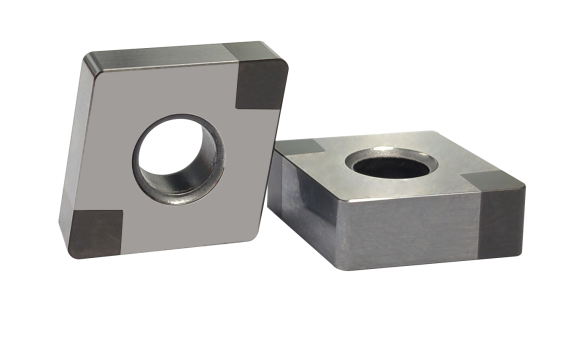

Hard turning is also known as the "turning instead of grinding" process. Although this technology has been around for a long time, when faced with strict processing conditions, the performance and stability of hard turning tools are extremely high. Especially in situations with strict dimensional tolerances and surface roughness requirements, or under strongly interrupted cutting conditions, most companies will choose CBN inserts

In order to meet this challenge,Halnn Superhard has made unremitting efforts and developed CBN inserts of BN-H05 grade, BN-H10 grade and BN-H21 grade. These three inserts have shown significant advantages for continuous cutting, medium interrupted cutting and strongly interrupted cutting conditions. In addition, Halnn Superhard also provides a variety of processing solutions such as coatings, chip breakers, wipers, etc. to meet different processing needs, further consolidating its leading position in the field of hard turning.

There are four types of Halnn hard turning CBN inserts, such as we have soild CBN,PCBN,Brazed CBN The grade we have BN-S20,BN-S200,BN-H05,BN-H10 , BN-H11,BN-H20.We also can add coating on CBN

Application fields mainly include the automotive industry, gears, bearings, ball screws, etc.

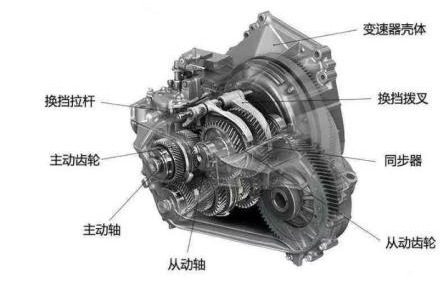

In the automotive manufacturing industry, hard turning is widely used for processing transmission parts. For example, in the manufacture of transmission gear shafts, hard turning not only provides the required accuracy but also enables the completion of a large number of machining tasks in a short time. This greatly improves production efficiency.

In summary, hard turning, as an efficient metal processing technology, not only improves production efficiency and reduces costs, but also improves product quality .

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone