Common processing workpieces: wind power bearings, wind power gears, wind power blades, etc.

Recommend CBN and Carbide Tools inserts for Wind Power Industry

CBN Inserts

|

|

|

|

|

RNGN CBN inserts | RNMN CBN inserts | RCMX-V CBN inserts | RCMN CBN inserts | DNGA CBN inserts |

|

|

|  | |

TNGA CBN inserts | CNGA CBN inserts | TNGA CBN inserts | RCGX-V/Y(Full face) | WCGW PCD inserts( Full face) |

The advantage of CBN inserts

High hardness

Excellent both abrasion resistance and impact resistance;

High cutting efficiency and long tool life;

Patented product, non-metal adhesive CBN inserts.

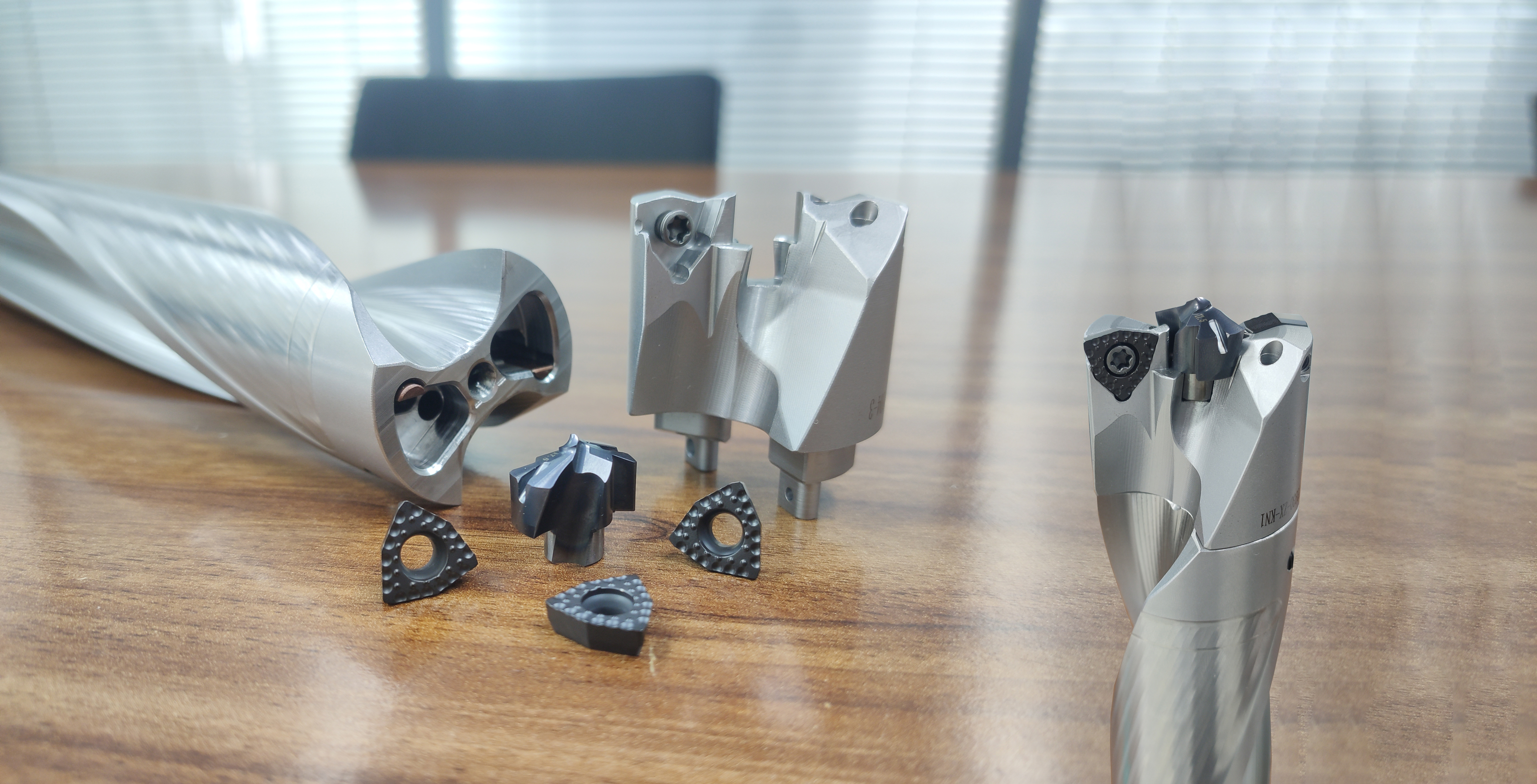

The Crown Drill

The advantages of Crown drill:

The crown drill has a special groove design and the central transverse cutting tool has high strength and a centering effect.

lt can achieve better hole machining size and hole wall quality under ultra-high feed rates.

The holder is made of high-quality imported alloy steel. Through long-term application experience, it is designed with a special chip breaker groove and drill handle design, which can achieve extremely high system rigidity and strength.

The same type of drill handle can be fitted with a certain range of drill tips to achieve a higher economy.

Processing case

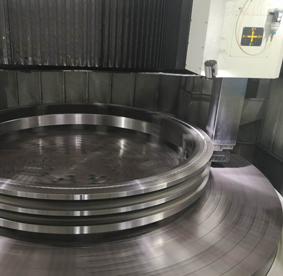

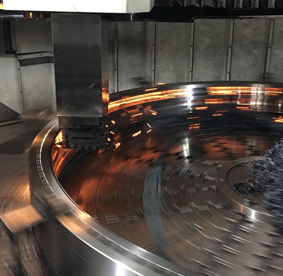

Processing part: Wind power bearing, Inner Ring Rib |  |

Processing size: 2750mm | |

Material: 42CrMo4 | |

Hardness of Bearing: 58-63 HRC | |

Surface Roughing: Ra 0.4 | |

Inserts Type:BN-H200 RNGN090300 | |

Machining way:Roughing | |

Machining parameter:Vc=190m/min Fr=0.32mm/r, Ap=0.6-0.7mm | |

Machining way: Finishing | |

Machining parameter:Vc=215m/min,Fr=0.2mm/r,ap=0.2mm |

| Processing part: Wind power bearing, Outer Ring Raceway |

Processing size: 2750mm | |

Material: 42CrMo4 | |

Hardness of Bearing: 58-63 HRC | |

Inserts Type:BN-H200 RNGN090300 | |

Machining way:Roughing | |

Machining parameter:Vc=190m/min, Fr=0.43mm/r, Ap=1mm | |

Machining way: Finishing | |

Machining parameter:Vc=260m/min,Fr=0.2mm/r,ap=0.1mm |

Part: Reducer gear Processing site:Inner tooth apex Size:φ1300 Other solid CBN: RNMN090400 Machining parameter:Vc=80m/min Fr=0.3 Ap=0.3 Difficulties:One insert cannot complete processing and breakdown Halnn PCBN BN-H200: RNMN090300 Machining parameter: Vc=100m/min Fr=0.3 Ap=0.3 Tool life: Machining 2 PCS with one cutting edge |

|

Part: Gear for Wind Power Reducer Rough turning end face and inner hole Original CBN insert, CNGA120412 Original parameters: VC=120m/min, f=0.2, ap=0.7, diameter D=509 Lifespan: 2 products for a single cutting edge Improved CBN insert, Halnn RNGN060300 Processing parameters: VC=119m/min, f=0.3, ap=0.7, diameter D=509 Lifespan: 2 products for a single cutting edge With the same parameters, under the hard conditions of ensuring a minimum lifespan of 2 PCS, circular blades exhibit more stable performance in complex working conditions. |

|

Part: Gear for Wind Power Reducer Fine turning end face and inner hole Original CBN insert, DNGA150412 Original parameters: VC=130m/min, f=0.1, ap=0.2, diameter D=509 Lifespan: 1 product for a single cutting edge Improved CBN insert, Halnn WNGA080408-WH with wiper Processing parameters: VC=150m/min, f=0.3, ap=0.2, diameter D=509 Lifespan: 1 product for a single cutting edge For the inner hole of the large diameter gear ring, the roughness of the workpiece can still be controlled within 0.6 after the deep inner hole machining of the Halnn BN-H200. The processing time of a single piece has been reduced from 24 minutes to 8 minutes, and the processing efficiency has been increased by three times. |

|

Heat-treated bearings, such as wind turbine bearings, metallurgical bearings, and wheel hub bearing units, generally have a hardness above HRC50, which puts high demands on the wear resistance and life of the tool.

Large-scale bearings, such as wind turbine bearings, have large diameters. After heat treatment, the machining allowance is 2-6mm, and the machining allowance is uneven. Moreover, there are oil holes in the lunar groove of the outer ring raceway of the machining part. The tool needs good impact resistance and toughness. It will break easily. At the same time, bearings have higher requirements for accuracy and surface roughness. For example, the accuracy tolerance of the raceway radian of the wind turbine bearing is 0.08, and the surface roughness of the raceway is Ra0.4.

With the continuous development of the modern tool industry, the cubic boron nitride (CBN) tool BN-H200 material developed by the superhard material industry effectively solves the problem of difficult bearing machining and can meet the requirements of high quality, high efficiency and low cost at the same time.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone