In the process of processing auto parts, the tool often has problems such as wear resistance, low efficiency or high hardness of the parts, and the processing does not move. For these reasons, Halnn has developed a variety of grades to deal with different materials of auto parts. The specific cutting parameters are as follows

Processing materials | Processing type | Recommended CBN cutting parameters | Recommended CBN grade | ||

Cutting speed Vc(m/min) | Cutting Depth ap(mm) | Feed Rate Fr(mm/r) | |||

Hardened Steel (hardness ≥HRC45) | Finishing | 90-250 | ≤1 | 0.05-0.35 | BN-H05, BN-H10, BN-H11, BN-H21, BN-H20 |

Grey cast iron | Roughing | 400-1200 | 1-10 | 0.2-1.0 | BN-S300 |

Finishing | 600-2000 | ≤1 | 0.05-0.3 | BNK30 | |

Powder metallurgy | Roughing | 80-150 | ≥0.5 | 0.1-0.5 | BNK30, BN-K10, BN-K50, BN-H21 |

Finishing | 90-180 | ≤0.5 | 0.1-0.2 | ||

Workpiece material | Recommended PCD cutting parameters | Recommended PCD grade | ||||||

Cutting speed Vc(m/min) | Cutting Depth ap(mm) | Feed Rate Fr(mm/r) | ||||||

Aluminum alloy | 4-8%Si | 100-5000 | 0.03-0.5 | 0.1-3.0 | CDW010 | CDW302 | CDW005 | CDW850 (CDW20-1) |

9-13%Si | 100-3000 | 0.03-0.5 | 0.1-3.0 | CDW010 | CDW302 | CDW850 (CDW20-1) | ||

>13%Si | 100-2500 | 0.03-0.4 | 0.1-2.5 | CDW010 | CDW302 | CDW025 | CDW850 (CDW20-1) | |

Tools for Auto Parts Machining | |||

|

|

|

|

Brake Discs/Drums

Brake discs/drums, as typical mass-produced Auto parts, mainly material is gray cast iron. And large enterprises mostly use special machines or automatic production lines for brake discs and brake drums for production, which have high performance requirements for machine tools and cutting tools. While ensuring the quality, the company pays more and more attention to the improvement of efficiency. For this, Halnn which can better meet the requirements of high-speed machining of brake discs and brake drums, Halnn CBN tool life and stability are 50% or even several times higher than that some brand CBN inserts.

BNK30, a new CBN grade developed by Halnn tools, adopts the optimal ratio of nano-scale binder and high-purity CBN particles.

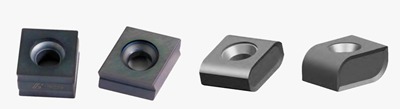

Recommended inserts and grades

|

|

|

|

|

|

CNMN/CNGN | SNMN/SNGN | SCGN | WNGA | TNGA | CNGA |

Roughing Brake discs and Brake drums: Insert grade: BN-S300, Insert types CNMN/SNMN

Finishing Brake discs and Brake drums: Insert grade BNK30, Insert types SCGN/CNGA/WNGA/TNGA/VNGA, etc.

High-speed cutting at cutting speed of 500-2000m/min, to meet the stable cutting of brake disc and brake drum parts, especially finishing, the performance advantage is more obvious.

At the same time, Halnn tools can also customize inserts such as wipers and coatings according to customer needs to help high-speed cutting of brake discs and brake drums.

Application cases

Workpiece: Brake Disc |

| ||

Material: GC250 (HT250), Hardness: HB210 | |||

Insert Type: BN-S300 CNMX120716(Positioning hole) | |||

Cutting parameters: Vc=800m/min, Fr=0.45mm/r, ap=2mm | |||

Processing method: Semi-finishing, Dry Cutting | |||

Insert grade | Cutting Speed | Efficiency | |

Halnn BN-S300 | 800m/min | Improved 6 times | |

ceramic inserts | 800m/min | ------- | |

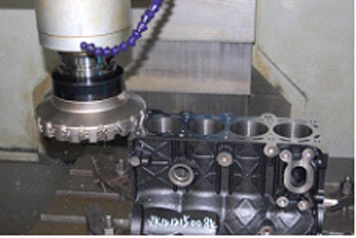

Engine block

Milling process: Halnn CBN insert BN-S300 is used, which has significantly improved productivity and stable cutting performance, which can advantageously replace international first-line brands such as Seco tools.

Boring process: BN-S300 grade or BNK30 grade is recommended, which has high cost performance and stable cutting performance, and is one of the representative works of localization of tools in the engine industry.

Cylinder port chamfering process: Customized according to customer needs, the advantages are stable cutting performance and high cost performance.

For the aluminum alloy engine block: Halnn PCD tools are selected for high-speed milling flat, the cutting speed can reach 3000m/min, and it has excellent processing characteristics. For the hole system, Halnn PCD reamers are recommended to improve tool life and ensure high dimensional accuracy and surface roughness.

| Workpiece: Engine Block | |||

Material: FC250(HB170~210) | ||||

Insert Type: BN-S300 SNEN090308 | ||||

Cutting parameters: Vc=1700 m/min, Ap=0.3mm, Fz =0.12mm/r | ||||

Processing method: dry cutting(Finish milling) | ||||

Insert grade | Feed Rate | Tool Life/edge | Efficiency | |

Halnn BN-S300 | 3670mm/min | 100 pieces | Improved 0.6 times | |

Some brand CBN | 2200mm/min | 80 pieces | / | |

Engine cylinder head

Finish milling cylinder head: BN-S300 grade Solid CBN insert is recommended, the productivity is significantly improved and the cutting performance is stable. It can advantageously replace international first-line brands such as Seco Tools.

Valve chamfering: customized according to customer needs, the advantages are stable cutting performance and high cost performance.

Turning valve seat ring: DCGW11T304 etc. is recommended for commonly types. The advantage is that high-speed cutting can be achieved and a higher finish can be obtained.

Boron cast iron cylinder liner

Cylindrical turning: BN-S300 grade of Solid CBN insert is recommended, which can be dry-cut, and its tool durability is N times higher than that of ceramic tools.

Grooving: customized according to customer requirements to obtain longer tool life and higher production efficiency.

| Workpiece: Finish turning Cylindrical | |||

Material: Boron cast iron | ||||

Insert Type: BN-S300 SNMN120412 | ||||

Cutting parameters: Vc=850 m/min, Ap=0.5mm, Fz =0.25mm/r | ||||

Processing method: Wet cutting | ||||

Insert grade | Cutting speed | Machining beat | Tool Life/edge | |

Halnn BN-S300 | 850m/min | 23 s/piece | 120 pcs | |

Ceramic inserts | 500m/min | 40 s/piece | 25 pcs | |

Gear, Gear shaft

Recommend Grade and Process conditions

BN-H05 and BN-H11 grades for continuous process, with can high-speed cutting

BN-H10 and BN-H20 grades for Light interrupted cutting conditions, can withstand the impact of the keyway during hard turning, with stable performance

BN-H21 grade of PCBN insert is recommended for heavy interrupted cutting conditions, with good toughness, impact resistance and stable performance

Cases of Hardened Steel Gear Process

Workpiece: Gears, Inner hole,Light interrupted |

| ||

Materials:20CrMnTi | |||

Hardness: HRC58-62 | |||

Type:BN-H10 CCGW09T304 | |||

Cutting Parameter:Vc=135m/min,Fr=0.08mm/r,ap=0.25mm | |||

Cutting condition: Dry Cutting | |||

Tools Life | Efficiency | Inserts | |

1000 Pcs | Improve 22% | Halnn CBN BN-H10 Grade | |

600 Pcs | ---- | Other CBN Grade | |

Gearbox housing

Milling process: The BN-S300 grade for Solid CBN insert is recommended, which significantly improves the production efficiency of the coated carbide tool and increases the tool life by N times.

Boring process: PCBN inserts (including composite and brazed) are recommended, which can significantly improve production efficiency and achieve higher surface quality.

For aluminum alloy gearbox housing: Halnn tools can provide PCD milling, boring, reaming, drilling and other tools, which greatly improves production efficiency, ensures high dimensional accuracy and reduces production costs.

Pulley

The material is HT250, which is mainly used for end face machining. PCBN inserts (including composite and brazed types) are recommended. The advantages are: stable cutting performance and doubled production efficiency.

Cv Joint

Process: Hard turning process after hot, recommended PCBN inserts, cost-effective, stable cutting performance, and can intermittent machining.

| Workpiece: CV joint (finish) | |||

Material: Hardened Steel | ||||

Insert Type: BN-H10 TNGA160408 | ||||

Cutting parameters: Vc=190m/min, Fr=0.15mm/r, ap=0.15mm | ||||

Processing method: Dry cutting | ||||

Insert grade | Cutting speed | Tool Life/edge | Tool cost | |

Halnn BN-H10 | 190m/min | 355 pcs | 0.06 RMB/pc | |

Other CBN inserts | 170m/min | 370 pcs | 0.1 RMB/pc | |

Synchronized pulley

The material is powder metallurgy. Due to the porous structure, the cutting edge of the cutting tool wears sharply. At this time, Halnn tools PCBN insert is recommended, the advantages are: sharp inserts, stable cutting performance, and tool life is increased by 50% compared to other brands CBN tools.

| Workpiece: Synchronized pulley(Finishing) | ||

Material: Powder metallurgy | |||

Insert Type: BN-K50 DCGW11T304 | |||

Cutting parameters: Vc=150m/min, Fr=0.1mm/r, ap=0.2mm | |||

Processing method: Dry cutting | |||

Insert grade | Roughness | Tool Life/edge | |

Halnn BN-K50 | ≤Ra0.8 | 450 pcs | |

Other CBN inserts | Ra1.0 | 300 pcs | |

Synchronizer Gear Hub

The material is powder metallurgy. Due to the porous structure, the cutting edge of the cutting tool wears sharply. At this time, Halnn PCBN inserts are recommended. The cutting performance is stable, and the tool life is 45% higher than that other brands CBN tools.

| Workpiece: Synchronizer Gear Hub(Finishing) | ||

Material: Powder metallurgy | |||

Insert Type: BN-K50 DCGW11T304 | |||

Cutting parameters: Vc=500m/min, Fr=0.1mm/r, ap=0.2mm | |||

Processing method: Dry cutting | |||

Insert grade | Tool Life/edge | Efficiency | |

Halnn BN-K50 | 145 pcs | Improved 45% | |

Other CBN inserts | 100 pcs | / | |

Wheel hub

The material is aluminum alloy. Halnn PCD tools are recommended. The cutting performance is more stable, the tool service life is longer, and the efficiency and cost are improved. Halnn can provide non-standard customized services.

Pistons

The material is aluminum alloy. Halnn PCD tools are recommended, which can be processed at high speed, with stable product quality, high precision and long life. And provides non-standard customization services.

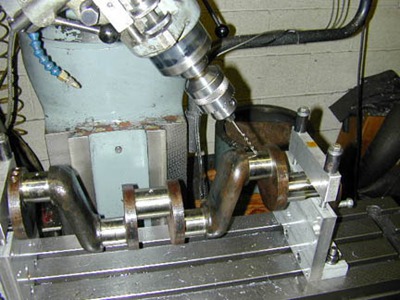

Camshaft

Specification range

Diameter: 320-800mm

Width range: 15-60mm

Customized external milling cutterhead according to customer crankshaft.

Insert Type

Applications

The diameter of insert: 320mm Cutting speed: 120m/min Cutting depth: 5 mm

Feed rate:0.15mm/min Machine: Special machine

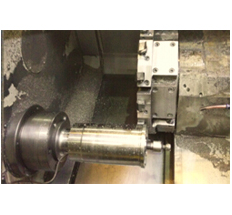

Crankshaft

Non-standard insert

Product feature

1. The insert adopts high toughness matrix with high quality CVD coating to provide higher processing efficiency and tool life;

2. Grinding precision insert combined with optimized tooth arrangement design, to make workpiece surface achieving the pre-grinding standard;

3. Cutting parts adopt segmented modular installation design, easy to unload and adjust;

4. Excellent cutting performance, to achieve a high chip removal efficiency.

Process Case

| Comparision test | Current Tool | HALNN Tool |

| Insert | European 134-C03 48 Pieces 122-C03 16 Pieces H3-03 16 Pieces | 680-002X12012060A10 HPA035B 680-002N14009507R34 HPA035B |

| Holder | MSDNN2020K12 | D280 Cutterhead |

| Vc(m/min) | 140 | 140 |

| N(min-1) | 159 | 159 |

| f(mm/rev) | / | / |

| F(mm/min) | 477 | 477 |

| ap(mm) | 3-4 | 3-4 |

| ae(mm) | / | / |

| Type of cooling | Dry-type | Dry-type |

| Tool wear | Normal wear/side milling insert broken edge(Must change insert by processing 300 workpieces) | Normal wear (Must change insert by procesing 300 workpieces) |

| tool life/cutting edge | 300 psc/cutting edge | 300 pcs/ cutting edge |

Product name: Crankshaft

Processed material: 42CrMo

Material hardness: HB256-295

Machine type: special machine

Industry type: Automobile industry

Customer requirement: improve processing surface quality, reduce tool cost

Comprehensive evaluation: Meet customer roughness requirement. According to the tool wear analysis, The Halnn tool wear is lighter than the current tool, still could continue processing. There is no breakage, just normal wear, solve the anti-breakage property of insert. Improve the stability of cutting tools.

Crankshaft Deep Hole Drilling

Product advantages:

The latest designed four-plane drill tip ensures good chip breaking effect;

Special groove and edge treatment, excellent chip holding capacity and smooth chip removal;

The use of cross-edge thinning technology greatly reduces axial resistance;

Selected heat-resistant and wear-resistant coatings greatly increase tool life;

For oil mist cooling, large-hole inlet rods are selected for better lubricity.

Application range:

Processing diameter range: 12D-50D

Effective drilling depth: 400mm

Application cases:

Workpiece: crankshaft Workpiece material: 42CrMo

Hardness: HRC28-32 Drilling depth: 150mm

Machine: vertical machining center

Drilling method: continuous machining

| Comparison test | Original inserts | Halnn inserts |

| Diameter | D8 internal coolant deep hole drill | D8 internal coolant deep hole drill |

| Vc(m/min) | 62.8m/min | 62.8m/min |

| F(mm/min) | 500mm/min | 500mm/min |

| n(r/min) | 2500r/min | 2500r/min |

| Processed Quantity | 180 pcs | 220 pcs |

Results: Under the same processing parameters, the life of Halnn’s insert increased by 22%.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone