Composite materials

Composite materials are mainly used in aviation, 3C, wind power and other industries. Composite materials include carbon fiber reinforced composite materials (CFRP), carbon-carbon composite materials, aluminum matrix composite materials, titanium matrix composite materials, copper matrix composite materials, metal matrix composite materials, etc.

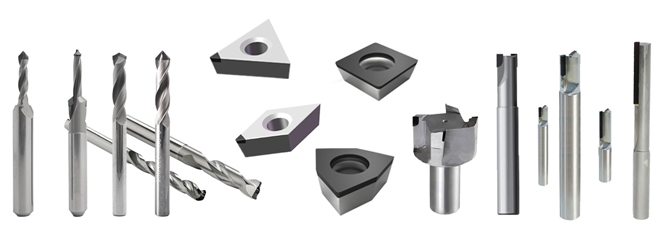

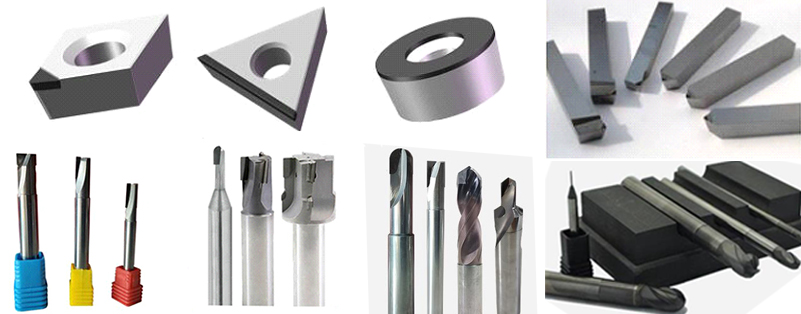

For composite materials, Halnn tools can provide milling cutters, reamers, drills, grooving, engraving and other tools, and also provide customized services according to customer needs.

Ceramic

Ceramic is a difficult material to cut. Mainly used in aerospace, machinery, medicine, mold and other industries. In the past, most customers mainly used grinding process. With the development of superhard cutting technology, diamond (PCD) tools are gradually replacing grinding and are increasingly used for ceramic machining. At the same, Halnn has also developed and launched a series of PCD turning and milling tools.

Graphite

Graphite is a non-metallic material and is widely used in graphite molds, graphite crucibles, and graphite battery plates.

Although graphite is a free-cutting material, it is easy to break due to brittleness, edge chipping, and tool wear during processing, which affects the surface quality of the product. Halnn tools, as a pioneer in the localization of superhard tools, has a good understanding of diamond tools, for graphite materials,Halnn has developed graphite turning tools, graphite milling cutters, graphite chamfer cutters, graphite diamond-coated tools through breakthroughs in materials, technology, and craftsmanship. The recognition not only effectively solves the problem of rapid tool wear, but also greatly improves production efficiency. CDW010 and CDW025 grades are the first choice.

Aluminum-based silicon carbide, abbreviated as AlSiC (SICP/Al or Al/SiC, SiC/Al), is a particle-reinforced metal matrix composite composed of silicon carbide (SiC) and granular aluminum. Materials, with excellent high hardness, high toughness, high plasticity, high modulus and other advantages, are widely used in aviation, aerospace, electronic chips, high-speed rail, satellites and other fields.

Common processing methods of aluminum-based silicon carbide composites include milling, drilling, etc., to process curved surfaces, holes, and grooves. In order to better control the cost, rough machining can be performed with carbide tools, and PCD tools can be used for milling and drilling for finishing. As a new type of modern composite material, aluminum-based silicon carbide composite material has many advantages, but it also has obvious disadvantages, that is, it is difficult to machine, the tool wears quickly, the production cost is high, and the efficiency is low. For aluminum-based silicon carbide composite materials, Halnn's commonly used tools include PCD milling cutters and PCD drill bits. Common grades are CDW010, CDW025, and CDW302, according to the composition of aluminum-based silicon carbide, different materials are selected for efficient processing.

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone