Component: Slurry Pump (Impurities pumps, mud pumps, water pumps), impeller, liner, Cylinder liner,etc

Materials: Cr15Mo3, Cr15Mo2Cu, KmTBCr12, Cr20, Cr26 High Chromium alloy cast iron, white cast iron

Selected CBN Grade: BN-K1 Solid CBN Insert

Advantages: High hardness, high strength, perfect balance of wear and impact toughness

Common Insert Types: SNMN1204, SNMN1207, CNMN1204, CNMN1207, RNMN1204, RNMN1207

Matching tool holder: CSRNR/L,CCLNR/L,CRGNR/L

Recommend inserts

|  |  |

RNMN/RNGN | SNMN/SNGN | CNMN/CNGN |

Application cases

| Workpiece: Slurry pump body | ||

Material: Cr26(Hardness HRC60) | |||

Insert Type: BN-K1 CNMN120712 | |||

Cutting parameters: Vc=75m/min, Fr=0.12mm/r, ap=2.5mm | |||

Processing method: dry cutting | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 CBN inserts | 85pcs | Normal wear | |

Some brand CBN | 35pcs | Damage rupture | |

| Workpiece: Slurry pump body | ||

Material: High-chromium white cast iron Cr26(Hardness HRC60) | |||

Insert Type: BN-K1 SNGN120712 | |||

Cutting parameters: Vc=75m/min, Fr=0.12mm/r, ap=2.5mm | |||

Processing method: dry cutting | |||

Insert grade | Tool Life/edge | Efficiency | |

Halnn BN-K1 CBN inserts | 85pcs | Improved 3 Times | |

Some Ceramic Inserts | 35pcs | / | |

Workpiece: Slurry Pump impeller |  | ||

Materials: High chromium cast iron Cr26(Hardness HRC60) | |||

Insert Type:BN-K1 SNMN120712 | |||

Cutting parameters:Vc=45m/min, Fr=0.25mm/r, ap=2.5mm | |||

Processing method: Heavy Interrupt dry Turning | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 | 11pcs | Normal wear | |

Some brand CBN | 3pcs | Damage rupture | |

Workpiece: Slurry Pump impeller |  | ||

Materials: High chromium cast iron(Hardness HRC58-62) | |||

Insert Type:BN-K1 RNMN120400 | |||

Cutting parameters:Vc=50m/min, Fr=0.25mm/r, ap=2.5mm | |||

Processing method: Heavy Interrupt dry Turning | |||

Insert grade | Tool Life/edge | Failure mode | |

Halnn BN-K1 | 2pcs | Normal wear | |

Some brand CBN | <1pcs | Damage rupture | |

High manganese steel is a commonly used wear-resistant steel in machinery industry, these wear parts usually have excellent performance: high strength, high toughness,high wear resistance, but the machinability of high manganese steel is poor,it mainly has the following difficulties:

(1) Plastic deformation, severe processing hardening;

(2) Large plasticity, easily to form BUE;

(3) Large cutting force, high toughness, not easy to break.

(4) Due to the large cutting force, the unit cutting power increases, the heat generated per unit time and high manganese steel itself poor thermal conductivity, the cutting zone temperature up to 1000 ℃, severe tool wear, tool life is low.

For these, Halnn tools has launched BN-K1 and BN-S20 grade solid CBN inserts, excellent fracture resistance, doubled production efficiency; N times longer than traditional tool life

Recommend inserts

|  |

RNMN/RNGN | SNMN/SNGN |

Common Insert Types: SNMN150716, RNMN200800

Halnn CBN Grade:

BN-K1(0701): Excellent toughness, wear resistance not well

BN-K1(0308): balance performance

BN-S20 & BN-S200(small inserts), Excellent wear resistance, toughness not well

Recommend Cutting Parameters:

Roughing: ap=5-6mm; Fr=0.4-0.6mm/r; Vc=45-75m/min

Finishing: ap=1-2mm; Fr=0.3-0.5mm/r; Vc=60-100m/min

Application cases

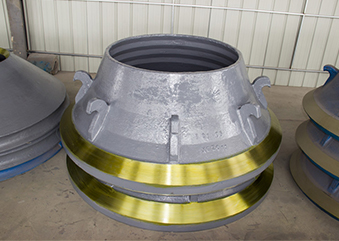

| Workpiece: Crushing Cone | |||

Material: High Manganese steel | ||||

Insert Type: BN-K1 SNMN150716 | ||||

Cutting parameters: ap=7.5mm, Fr=0.5mm/r, Vc=65m/min | ||||

Processing method: dry cutting | ||||

Insert grade | Cutting speed | Cutting Depth | Tool Life/edge | |

Halnn BN-K1 CBN | 65m/min | 7.5mm | 2pcs | |

Carbide Insert | 19m/min | 3.5mm | 0.5pcs | |

Workpiece: Crushing Cone |  | |||

Material: High Manganese steel | ||||

Insert Type: BN-K1 SNMN150716 | ||||

Cutting parameters: ap=6mm, Fr=0.6mm/r, Vc=50-75m/min | ||||

Processing method: dry cutting | ||||

Insert grade | Cutting speed | Efficiency | Tool Life/edge | |

Halnn BN-K1 | 50-75m/min | 45min/pcs | 2pcs | |

Carbide Insert | 10m/min | 270min/pcs | 0.5pcs | |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone